在工业锅炉领域,适配的组态屏的集成对于实现关键参数的高效监测、控制及可视化至关重要。大型锅炉对显示解决方案提出了严苛要求,需具备耐受恶劣运行环境的能力,同时为操作人员提供清晰直观的界面。本文旨在探讨为大型锅炉选择适配的组态屏的重要性,并重点介绍在各类工业应用中有效应用组态屏的解决方案。

一、大型锅炉领域选用组态屏的重要性

1. 实时监测与控制

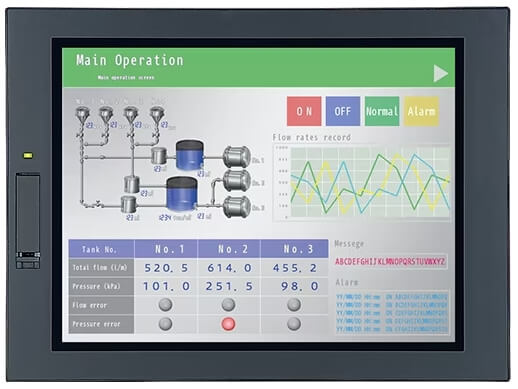

组态屏在大型锅炉中发挥着关键作用,可实现对温度、压力、燃料消耗及运行状态等关键参数的实时监测与控制。清晰准确的显示界面使操作人员能够及时做出决策并调整参数,以确保锅炉运行效率。

2. 诊断反馈与警报

这些显示屏提供诊断反馈和警报,使操作人员能够及时识别并解决与锅炉效率、维护需求及安全问题相关的问题。组态屏上的视觉指示器有助于实现主动维护和故障排除,确保锅炉运行不中断。

二、组态屏在大型锅炉领域应用的解决方案

1. 高分辨率与清晰度

在选择大型锅炉的组态屏时,优先考虑高分辨率和清晰度的显示屏至关重要,以精确显示详细的锅炉参数、趋势分析和系统状态。清晰的视觉效果提升操作人员在锅炉运行过程中的可见性和决策能力。

2. 触摸屏界面

在组态屏中集成触摸屏功能,可通过触控输入命令、配置设置及访问全面的锅炉控制系统,提升用户体验。触摸屏显示屏简化操作流程,提升响应速度。

3. 坚固耐用的工业级设计

用于大型锅炉的组态屏应采用坚固耐用的工业级设计,能够承受极端温度、振动以及潮湿和烟尘环境,确保在工业环境中长期可靠运行。

4. 与锅炉控制系统兼容

选择与大型锅炉应用中常用控制系统和通信协议兼容的组态屏,实现显示屏与锅炉控制组件之间的无缝集成和数据交换。

5. 变光条件下增强的可视性

选用在变光条件下(包括锅炉房和工业设施中常见的强光或低光环境)具有增强可视性的组态屏。配备可调节亮度和防眩光特性的显示屏可为操作人员提供最佳可视性。

三、组态屏的其他有效应用

1. 燃气轮机监控系统

燃气轮机监控系统采用组态屏展示实时性能数据、运行参数及诊断信息,使操作人员能够监控涡轮机效率并迅速响应运行变化。

2. 水处理厂控制面板

集成于水处理厂控制面板的组态屏为操作人员提供水质参数、处理流程及系统状态的清晰可视化展示,支持水处理操作的有效管理。

3. 发电控制室

在发电控制室中,组态屏提供全面的显示界面,用于监控发电厂运行状态、电网连接情况及设备状态,协助操作人员维持电网稳定性和能源生产效率。

4. 工业炉窑接口

工业炉窑依赖组态屏展示温度曲线、加热循环及报警通知,便于在工业制造中实现对热过程和材料处理的精准控制。

5. 石油化工过程可视化

石油化工厂利用组态屏可视化复杂工艺参数、化学反应及安全联锁,赋能操作人员有效监控并优化石油化工生产流程。

综上所述,选择合适的组态屏对提升大型锅炉及其他各类工业设备和系统的功能性和操作性至关重要。通过重点考虑分辨率、触摸屏功能、坚固耐用设计、兼容性和可视性等因素,工业专业人员可确保组态屏与系统无缝集成,从而支持跨多种工业应用的运营效率和数据可视化。组态屏的灵活性和有效性凸显了其在推动工业环境中创新与互联方面的关键作用,最终为各工业领域的安全性、生产力和运营卓越性做出贡献。