TFT (Thin-Film Transistor) screens have become indispensable components in running equipment across various industries, providing essential interfaces for monitoring, control, and operational feedback. This article explores the diverse applications and technological advancements that make TFT screens suitable for running equipment, enhancing efficiency, safety, and user interaction.

Importance of TFT Screens in Running Equipment

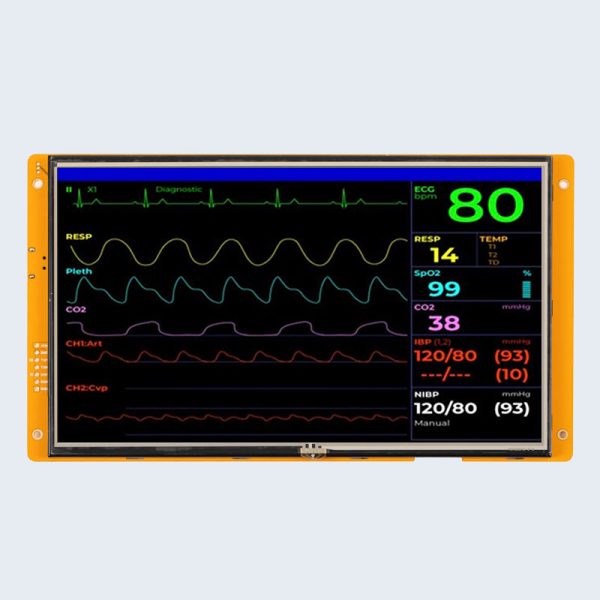

TFT screens play crucial roles in running equipment by offering real-time data visualization, operational controls, and diagnostic capabilities. They enable operators and users to monitor performance metrics, adjust settings, and respond to alerts or alarms promptly, ensuring optimal operation and minimizing downtime.

Enhancing Operator Control in Manufacturing

In manufacturing environments, TFT screens integrated into running equipment enhance operational control and production efficiency. Operators can oversee production processes, monitor machine performance, and adjust parameters via intuitive touchscreen interfaces. This capability facilitates rapid response to production challenges, improves throughput, and ensures consistent product quality.

Monitoring and Maintenance in Industrial Machinery

Industrial machinery relies on TFT screens for monitoring critical parameters such as temperature, pressure, and motor speed. TFT displays provide operators with clear visualizations of machine status, maintenance schedules, and diagnostic data. This information enables proactive maintenance planning, minimizes unplanned downtime, and extends equipment lifespan through timely interventions.

Safety and Control in Heavy Equipment

Heavy equipment in construction, mining, and transportation sectors benefit from TFT screens that serve as central displays for safety monitoring and operational control. Operators can access real-time data on equipment performance, environmental conditions, and proximity hazards. Enhanced visibility and touchscreen functionalities improve situational awareness, reduce operational risks, and enhance overall workplace safety.

Integration with IoT for Smart Equipment

The integration of TFT screens with IoT (Internet of Things) technology transforms running equipment into smart systems capable of real-time data exchange and remote monitoring. TFT screen facilitate connectivity with sensors, actuators, and cloud-based platforms, enabling predictive maintenance, performance optimization, and operational insights. This connectivity supports decision-making processes and enhances equipment reliability across diverse industries.

Customization for Specific Applications

TFT screens offer flexibility in customization to meet specific application requirements across different running equipment. Manufacturers can tailor screen sizes, resolutions, and interface designs to integrate seamlessly into various equipment types and operational environments. Customizable features include user interface layouts, data visualization formats, and compatibility with industry-specific communication protocols.

Durability and Environmental Resilience

Running equipment operates in challenging environments characterized by vibrations, dust, humidity, and temperature fluctuations. TFT screens designed for industrial applications feature durable construction with protective coatings, ensuring resilience against environmental stressors. These screens undergo rigorous testing for reliability and performance, maintaining functionality under demanding conditions and contributing to operational continuity.

Future Innovations in TFT Screen Technology

Looking ahead, TFT screens are poised to evolve with advancements in display technology and smart functionalities. Future trends may include the adoption of flexible and transparent TFT displays for unconventional equipment configurations and innovative user interfaces. Integration with AI algorithms for machine learning and autonomous decision-making capabilities could further enhance equipment performance and operational efficiencies.

Conclusion

In conclusion, TFT screens are integral components in running equipment across industries, providing critical interfaces for monitoring, control, and optimization. Their ability to deliver real-time data visualization, facilitate operational adjustments, and support integration with smart technologies underscores their importance in enhancing efficiency, safety, and productivity. As technology continues to advance, TFT screen will continue to play a pivotal role in driving innovation and improving performance in running equipment worldwide.