在工业机械领域,显示技术的重要性不言而喻。串口品屏凭借其卓越的性能特性、坚固耐用的设计以及对各种工业环境的适应性,已成为首选技术。本文将探讨串口显示屏在工业机械中的适用性,重点介绍其特点、优势、应用场景及未来发展趋势

了解串口屏技术

什么是串口屏?

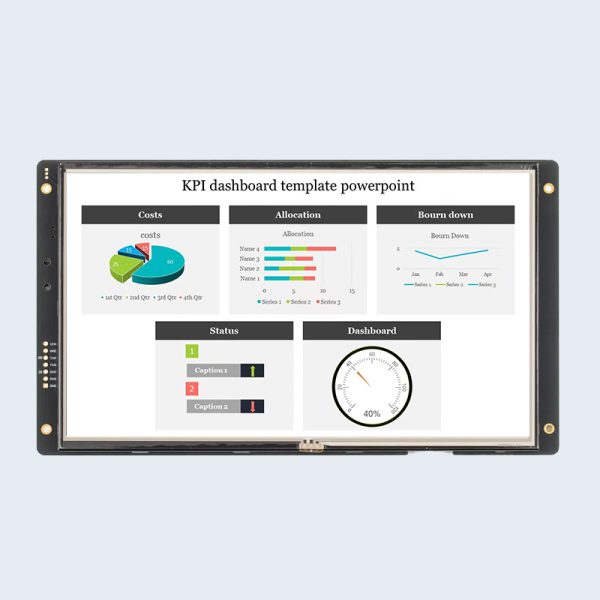

串口屏是一种利用薄膜晶体管技术提升图像质量和响应速度的液晶显示屏(LCD)。串口屏中的每个像素由独立的晶体管控制,从而实现更准确的色彩还原和更快的刷新率。这项技术显著提升了屏幕的视觉性能,使其成为对清晰度和细节要求严苛的应用场景的理想选择。

串口屏的关键特性

- 高分辨率:串口屏提供高分辨率图像,对于需要详细视觉效果的应用至关重要。其显示复杂图形的能力使其适用于控制面板和监控系统。

- 宽视角:与传统LCD相比,串口屏技术可实现更宽的视角。这一特性在工业环境中尤为重要,因为多个操作员可能需要同时查看显示屏。

- 快速响应时间:串口屏的快速响应时间可有效减少运动模糊,这对实时数据监控和控制至关重要。

- 鲜艳色彩:串口屏采用先进色彩滤光片,可呈现鲜艳准确的色彩,提升用户体验。

串口屏在工业机械中的优势

耐用性和可靠性

串口屏在工业机械中的主要优势之一是其耐用性。工业环境常使设备暴露于极端温度、湿度和振动等严苛条件下。串口屏专为应对这些挑战而设计,确保长期稳定运行。此外,其坚固结构可有效防止意外撞击造成的损坏。

节能

串口屏以节能著称。与传统CRT(阴极射线管)显示屏相比,串口屏屏幕的功耗显著降低。这一特性不仅降低了运营成本,还促进了工业生产的可持续性。节能型显示屏与制造业日益重视环保实践的趋势相契合。

增强型用户界面

串口屏的交互功能可提升用户界面体验。触摸屏选项使操作员能够直接与设备互动,简化工作流程并提升运营效率。直观的界面设计缩短了新员工的学习曲线,使其能更快掌握设备控制操作。

串口屏在工业机械中的应用

制造自动化

在制造自动化领域,串口屏被应用于控制面板和监控系统。其实时数据可视化能力对监控复杂流程的操作人员至关重要。通过显示温度、压力、生产率等指标,串口屏屏幕支持快速决策和主动维护。

运输与物流

串口屏在交通运输与物流领域亦有广泛应用。在车辆中,这些显示屏作为仪表盘,提供速度、燃油量、导航等关键信息。在仓库中,串口屏屏幕通过显示实时库存水平和订单状态,协助库存管理,提升运营效率。

医疗设备

在医疗领域,串口屏被集成到各类设备中,包括患者监护仪和成像系统。其高分辨率和色彩准确性对于准确解读医疗数据至关重要。此外,其耐用性确保其能够承受医疗环境的严苛要求。

挑战与考虑

成本影响

尽管串口屏具有诸多优势,但其初始成本可能成为部分制造商的顾虑。投资高质量串口屏技术可能需要较高的前期支出。然而,这一成本可通过耐用性、效率及功能提升带来的长期效益得到合理化。

技术进步

随着技术不断发展,制造商需密切关注串口屏显示技术领域的最新进展。例如,有机发光二极管(OLED)显示技术可能在某些方面超越传统串口屏显示技术,提供替代解决方案。定期评估技术趋势对保持工业领域的竞争优势至关重要。

串口屏显示技术未来趋势

与物联网(IoT)的集成

串口屏在工业机械中的未来发展将更深入地与物联网(IoT)集成。随着行业持续采用智能制造实践,串口屏将在提供实时数据分析和可视化方面发挥关键作用。这种集成将使操作员能够基于实时数据做出明智决策,最终提升生产效率。

显示质量的提升

显示技术的不懈进步将进一步提升串口屏的质量。未来发展可能包括更高分辨率的屏幕、更准确的色彩还原以及更强的耐用性。这些技术进步将满足各行业不断变化的需求,确保串口屏在工业应用中保持领先地位。

结论

综上所述,串口屏凭借其耐用性、能效及增强型用户界面等诸多优势,非常适合工业机械应用。其应用范围涵盖制造自动化、交通运输和医疗设备,彰显其多功能性。尽管存在成本等挑战,但串口屏技术的长期效益和未来发展趋势表明其前景光明。随着行业持续发展,串口屏在提升运营效率和生产力方面的作用将愈发关键。

实施中的额外考虑因素

选择合适的串口屏

在为工业机械选择串口屏时,需考虑以下因素:

- 尺寸与分辨率:根据应用需求,显示屏的尺寸和分辨率需满足视觉要求。

- 工作环境:显示屏必须适应特定环境条件,包括温度范围及污染物暴露程度。

- 触摸屏功能:对于交互式应用,触摸屏技术可提升用户体验与效率。

- 与现有系统兼容性:显示屏需与现有机械设备及软件系统兼容,确保无缝集成。

培训与支持

为了充分发挥串口屏在工业机械中的优势,对操作人员进行适当的培训和支持至关重要。培训计划应重点介绍显示屏的功能,强调如何有效解读数据。此外,持续的技术支持可解决运行过程中可能出现的问题,确保显示屏始终处于最佳状态。

定期维护的重要性

预防性维护策略

在工业环境中,实施串口屏的预防性维护策略至关重要。定期检查和清洁可防止屏幕损坏和图像质量下降。应制定维护计划,确保显示屏始终处于最佳状态。

常见问题排查

操作人员应接受培训,能够排查常见显示问题,如屏幕闪烁或触摸屏无响应。早期识别问题可避免重大停机时间,确保机械设备顺畅运行。

结论

串口屏是现代工业机械不可或缺的组成部分。其独特特性和优势使其适用于从制造到医疗保健的各种应用。通过了解技术进展并实施维护和支持的最佳实践,行业可以利用串口屏提升生产力和运营效率。随着技术持续演进,串口屏将继续处于工业创新的前沿,塑造未来机械接口的形态。

本综合概述强调了串口屏在工业机械中的重要性,阐述了其特性、应用及未来发展趋势。通过采用这些技术,行业可为在日益竞争激烈的市场中取得成功奠定坚实基础。.