TFT screens play a pivotal role in modern dry cleaning machines, providing essential interfaces for operation, control, and monitoring. This article explores the various applications and technological advancements that make TFT screens suitable for dry cleaning machines, enhancing efficiency, usability, and maintenance.

Importance of TFT Screens in Dry Cleaning Machines

TFT screens serve critical functions in dry cleaning machines by offering operators clear visual displays of operational parameters such as temperature settings, cycle progress, solvent levels, and maintenance alerts. They enable users to monitor real-time data, adjust cleaning parameters, and troubleshoot issues via intuitive touchscreen interfaces, ensuring optimal performance and prolonging equipment lifespan.

Operational Control and Efficiency

In dry cleaning operations, TFT screens facilitate operational control and efficiency by centralizing control functions into a user-friendly interface. Operators can initiate cleaning cycles, select programmable settings for different fabric types, and monitor energy consumption metrics. Touchscreen capabilities allow for seamless interaction, reducing manual errors and optimizing workflow productivity in commercial and industrial settings.

Integration with Automated Systems

Modern dry cleaning machines integrate TFT screens with automated systems for enhanced functionality and reliability. TFT screens support connectivity with PLCs (Programmable Logic Controllers), IoT (Internet of Things) platforms, and remote monitoring systems. This integration enables predictive maintenance scheduling, real-time performance analytics, and remote diagnostics, minimizing downtime and improving serviceability.

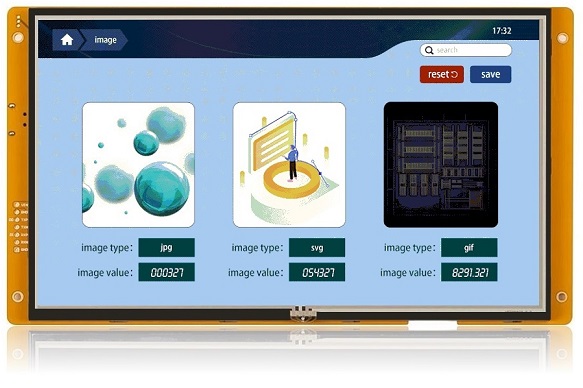

User-Friendly Interface Design

TFT screens offer customizable interface designs tailored to meet specific user preferences and operational requirements in dry cleaning applications. Operators can personalize screen layouts, adjust color schemes, and configure shortcut menus for quick access to frequently used functions. This customization enhances usability, simplifies training for new operators, and promotes consistent operational standards across multiple machines.

Monitoring and Maintenance Alerts

TFT screens facilitate proactive maintenance in dry cleaning machines by displaying diagnostic alerts, service reminders, and performance logs. Operators receive notifications for filter changes, solvent replenishment, and component inspections based on preset thresholds or operational hours. Touch-sensitive controls enable immediate response to maintenance alerts, ensuring equipment reliability and adherence to regulatory standards.

Energy Efficiency and Sustainability

Energy efficiency is a key consideration in dry cleaning operations, and TFT screen contribute to reducing energy consumption through optimized control algorithms and real-time monitoring capabilities. Screens display energy usage metrics, cycle efficiency reports, and environmental impact assessments. This information empowers operators to implement eco-friendly practices, minimize resource consumption, and meet sustainability goals.

Durability and Resistance to Chemical Exposure

Dry cleaning machines operate in environments exposed to chemicals, heat, and mechanical stress. TFT screens designed for industrial applications feature durable construction with chemical-resistant materials, anti-corrosion coatings, and sealed enclosures. These screens undergo rigorous testing for reliability, ensuring continued performance under harsh conditions and extending service life in commercial dry cleaning facilities.

Future Innovations in TFT Screen Technology for Dry Cleaning Machines

Looking ahead, TFT screens for dry cleaning machines are poised to evolve with advancements in display technology and smart functionalities. Future trends may include the adoption of OLED (Organic Light-Emitting Diode) displays for improved energy efficiency and enhanced visual clarity. Integration with AI (Artificial Intelligence) algorithms could enable predictive maintenance algorithms, anomaly detection, and adaptive cleaning protocols based on fabric type and soil levels.

Conclusion

In conclusion, TFT screens are indispensable components in modern dry cleaning machines, enhancing operational control, efficiency, and sustainability. Their ability to deliver intuitive interfaces, support automated systems, and withstand harsh operating conditions underscores their importance in optimizing dry cleaning processes and maximizing equipment performance. As TFT screen technology continues to advance, it will drive innovation and elevate standards in efficiency, sustainability, and user experience in the dry cleaning industry worldwide.