随着科学技术的不断发展,机器人手臂在自动化设备中发挥着越来越重要的作用。机器人手臂具有灵活性、高精度和高效率等特点,使其在各行业生产过程中得到广泛解决方案。本文将深入探讨机器人手臂在自动化设备中的解决方案,并分析其带来的优势与挑战。

1 智能生产与机器人手臂的背景与概念

- 智能生产是指借助先进信息技术、传感器和控制系统实现生产过程的自动化与智能化。智能生产的目的是提高生产效率、降低成本、提升产品质量并确保生产安全。

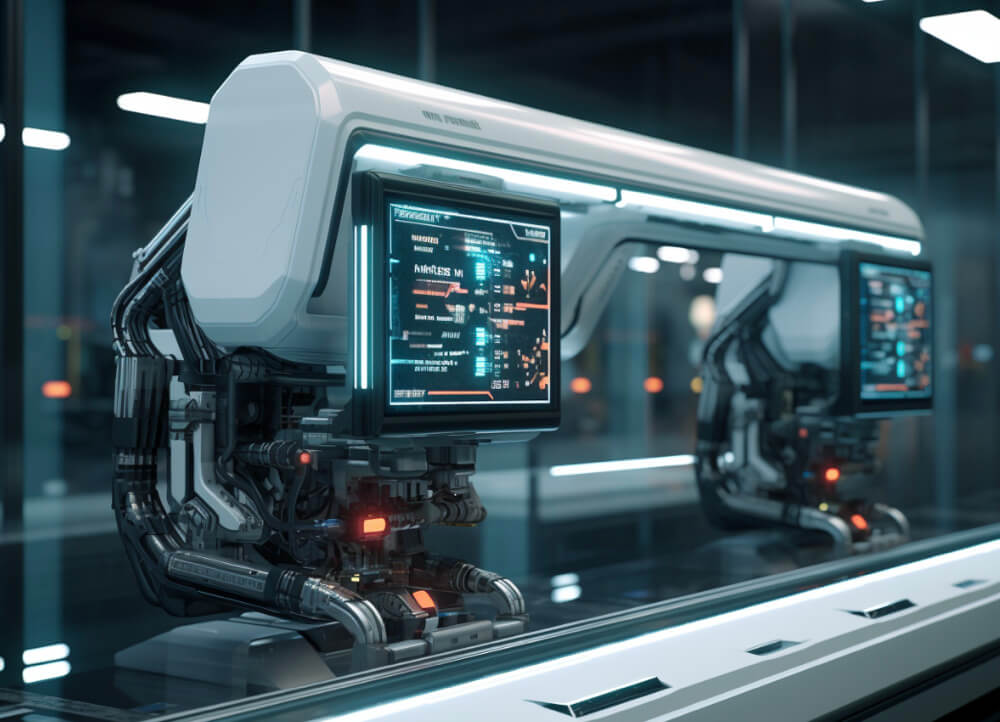

- 作为智能生产的重要组成部分,机器人手臂在各个领域得到广泛解决方案。机械臂是一种能够模拟人类手臂运动的机械设备,由多个连杆组成,通过电机和传动装置实现运动。机器人手臂的灵活性和高精度使其能够完成装配、搬运、焊接等各种复杂任务。

机器人手臂在自动化设备中的解决方案机器人手臂在自动化设备中得到广泛解决方案。以下将以几个典型领域为例进行讨论。

2.1 制造业在制造业中,机器人手臂可完成各种复杂的装配任务。其高精度和灵活性使在狭小空间内实现精准部件装配,从而提升生产效率和产品质量。

2.2 汽车制造在汽车制造过程中,机器人手臂可完成喷涂、焊接、装配等多个工序。机器人手臂的高速度和高精度使其能够快速完成复杂任务,提升汽车生产的效率和质量。

2.3 农业生产 机器人手臂在农业生产中也发挥着重要作用。例如,在园艺领域,机器人手臂可执行果园中的采摘和种植管理等任务。机器人手臂的高效率和自动化特性可大幅提升农业生产的效率和产量。

2.4 物流与仓储 在物流与仓储领域,机器人手臂可用于货物搬运、库存管理等任务。其高速与高精度特性可实现物流与仓储过程的自动化与高效化。

- 机器人手臂的优势与挑战 机器人手臂在自动化设备中具有诸多优势,但也面临一些挑战。

3.1 优势 机器人手臂具有以下优势:

- a) 效率:机器人手臂能够快速完成复杂任务,提升生产效率。

- b) 灵活性:机器人手臂可适应不同工作环境和工件形状,具有较强的适应性。

- c) 精度:机器人手臂的运动可实现精准控制,支持高精度操作。

3.2 挑战 机器人手臂在解决方案过程中也面临一些挑战:

- 成本:机器人手臂的制造和维护成本相对较高,这限制了其在某些领域的推广和解决方案。

- 复杂性:机器人手臂的控制和编程相对复杂,需要专业技术人员进行操作和维护。

- 安全性:机器人手臂的高速度和高扭矩可能导致潜在的安全隐患,因此需要采取相应的安全措施。

解决这些挑战需要采取适当的策略和方法,如提升操纵器的性能和稳定性、降低成本、加强安全管理等。

未来发展趋势在智能制造的未来,机器人手臂将继续发挥重要作用,呈现以下发展趋势:

- 智能化:机器人手臂将与人工智能技术相结合,实现更高级的自动化和智能化。

- 人机交互界面:机器人手臂将具备更友好的用户界面,使操作更加便捷。

- 网络连接:机器人手臂将通过网络实现远程控制和数据共享,提升生产灵活性与效率。

2 机器人手臂在自动化设备中的解决方案

作为自动化设备的重要组成部分,机器人手臂被广泛解决方案于各个领域。以下是一些典型的解决方案场景:

- 制造 在制造领域,机器人手臂可执行搬运、组装等多种生产任务。机器人手臂能精准拾取和放置物体,提升生产效率和产品质量。此外,机器人手臂还能完成焊接、切割等复杂加工操作。

- 医疗领域 在医疗领域,机器人手臂可用于手术辅助和康复治疗。机器人手臂能进行高精度手术操作,减少人为错误和伤害。此外,机器人手臂还能进行康复训练,帮助患者恢复运动功能。

物流与仓储 机器人手臂在物流与仓储领域广泛解决方案于物料搬运和分拣任务。

- 机器人手臂可自动将货物从一处转移到另一处,提升物流效率。同时,机器人手臂还能根据货物特性进行分类和分拣。

- 农业领域 在农业领域,机器人手臂可用于作物种植与收获。机器人手臂可自动完成种植和收获作业,减少人力投入并提升生产效率。此外,机器人手臂还能保护作物并防治病虫害。

- 太空探索 在太空探索领域,机器人手臂用于卫星维护和航天器操作。机器人手臂可在太空中执行维护工作,延长航天器寿命。此外,机器人手臂还能协助航天器完成采样和探索等任务。

3 机器人手臂在自动化设备中的优势

首先,机器人手臂具有灵活性和自动化优势。通过编程和传感器技术,机器人手臂可实现复杂运动和操作。它能根据不同任务需求灵活调整运动轨迹和操作模式。这对于制造、物流等需要高度自动化和灵活性的行业至关重要。机器人手臂可编程实现自动操作,减少人工参与和重复劳动,从而提升生产效率。

其次,机器人手臂具有高效率的优势。机器人手臂能够以更快的速度和更高的精度完成任务,与人工操作相比,可以大幅提升整体生产能力和效率。机器人手臂能在短时间内完成大量工作,从而缩短生产周期并加快产品交付速度。这对制造和物流行业至关重要,能够有效降低生产成本并提升利润。

此外,机器人手臂的精度也是其优势之一。机器人手臂可编程设置精确的运动轨迹和位置,实现非常精细的操作。这对于需要高精度操作的任务至关重要,如医疗手术和精密加工操作。机器人手臂的精度和稳定性可显著提升任务成功率和质量,并降低人为错误的可能性。

然而,机器人手臂也面临一些挑战。首先是安全问题。当机器人手臂执行工作任务时,可能会遇到人体或其他物体。如果操作不当或出现故障,可能会引发安全事故。因此,在设计和解决方案机器人手臂时,安全考虑非常重要,需要采取措施保障人员和财产安全。

其次是成本问题。机器人手臂的制造和维护成本相对较高,可能超出部分中小型企业的承受范围。此外,机器人手臂的解决方案还需要专业技术人员进行编程和操作,这会增加劳动力成本和培训成本。

此外,机械臂的适应性也是一个挑战。尽管机械臂在许多领域具有广泛的解决方案前景,但由于不同任务的特殊性和复杂性,机械臂的设计和编程可能需要根据具体需求进行定制化和优化。因此,需要持续进行研究和创新,以提升机械臂的适应性和灵活性。

作为自动化设备的重要组成部分,机器人手臂在各领域具有广阔的解决方案前景。其具有灵活性、高效率和高精度等优势,可提升生产效率并降低劳动力成本。然而,在实际解决方案中,机器人手臂也面临安全、成本和适应性等挑战。

未来,需要持续的研究与创新来解决这些挑战,进一步发展和解决方案机械臂。

作为自动化设备的重要组成部分,机械臂具备手臂的技术与方法。

4 自动化设备中机器人手臂的未来发展趋势

广阔的解决方案前景。随着技术的不断进步和工业化的发展,机器人手臂在各个领域发挥着重要作用。然而,在未来发展中,机器人手臂仍面临一些挑战与机遇。

首先,机械臂发展的一个趋势是智能化。随着人工智能和机器学习的快速发展,机械臂可以通过自动学习和自主决策提升智能水平。通过与传感器和视觉系统的结合,机械臂可以实现环境感知和目标识别,提升其适应不同场景和任务的能力。智能机械臂能够更好地应对复杂工作任务,提升生产效率和质量,减少人为操作中的错误和事故。

其次,机器人手臂的第二个发展趋势是协作。目前,机器人手臂大多独立工作,与人类工人分离操作。然而,随着人机协作需求的持续增长,机器人手臂需要具备与人类工人协作完成任务的能力。这要求机器人手臂能够感知人类肢体动作和意图,并通过安全控制和共享控制技术与人类工人协同工作。协作机器人手臂可提升工作灵活性与效率,同时改善工作环境安全性。

第三,机器人手臂的第三个发展趋势是无人化。随着无人技术持续成熟,机器人手臂可逐步实现无人化操作。在危险环境、太空探索、深海探测等特定场景,无人机器人手臂可替代人类作业,降低人类面临的危险与限制。通过无人化机器人手臂,可以提升工作安全性和效率,并拓展工作范围与潜力。

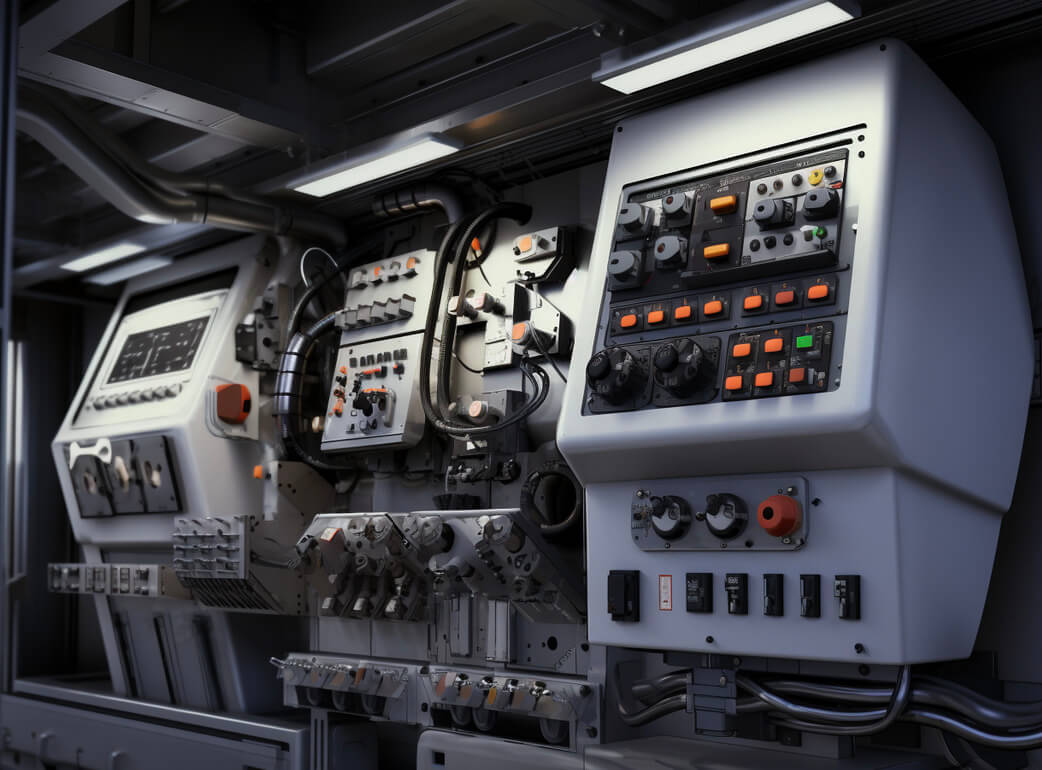

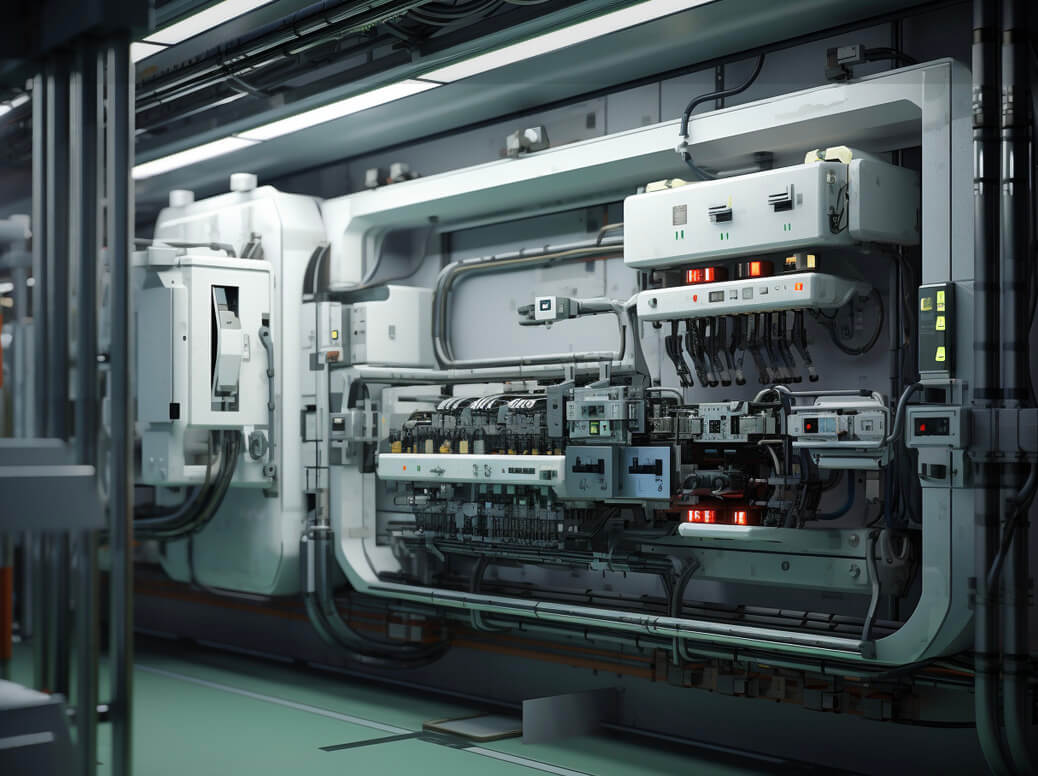

此外,机器人手臂的第四个发展趋势是集成化。当前的机器人手臂通常由多个独立部件组成,需要复杂的操作和编程才能工作。未来机器人手臂将更加注重集成化设计,通过模块化和标准化设计,实现不同部件的快速组装与调整。集成化机器人手臂能更好地适应不同任务和工作场景,减少安装调试的时间和成本。

在机器人手臂的未来发展中,我们仍需解决一些挑战。首先是安全问题。机器人手臂在工作过程中需与人类工人协同作业,因此安全至关重要。需采取措施保障人员安全,例如引入安全控制系统和传感器,实现机器人手臂的动态感知与早期预警。其次是成本问题。目前机器人手臂的制造成本和维护成本相对较高,可能超出部分中小型企业的承受范围。需降低机器人手臂成本,提升其市场渗透率和解决方案范围。最后是社会接受度问题。机器人手臂的普及还需要得到社会的认可和接受。我们需要加强机器人手臂技术的宣传和教育,使公众能够理解和接受机器人手臂的优势及解决方案前景。

5 机器人手臂在自动化设备中的重要性

作为自动化设备的重要组成部分,机器人手臂在现代工业生产中发挥着至关重要的作用。其出现与发展不仅提升了生产效率和质量,还改变了人们的工作和生活方式。本文将从三个方面探讨机器人手臂在自动化设备中的重要性:提升生产效率、增强工作安全性和促进技术创新。

首先,机器人手臂的出现极大提升了生产效率。与人工操作相比,机器人手臂具有更快的速度和更精准的动作,能在短时间内完成大量重复性任务。无论是在汽车制造、电子组装还是食品加工等行业,机器人手臂都能高效完成生产线上的各个环节。机器人手臂的高精度和可编程性使其在精密加工领域得到广泛解决方案。借助机器人手臂,制造商可提升产品生产速度和质量,降低生产成本,增强市场竞争力。

其次,机器人手臂提升了工作安全性。在高温、高压、危险物质等高危环境中,人类作业可能存在安全风险。机器人手臂可替代人类进行危险作业,保障工人安全。例如,在消防救援中,机器人手臂可进入危险区域进行搜救工作,降低消防员面临的危险和压力。此外,机器人手臂还可在高空、深海等特殊环境中作业,拓展工作范围与潜力。通过感知与控制系统,机器人手臂可实时感知周围环境,预警潜在危险并采取相应措施保障作业人员安全。

最后,机器人手臂的发展推动了技术创新。机器人手臂技术涵盖机械工程、电子技术、控制系统等多个领域。其研发与解决方案持续推动技术进步。例如,机器人手臂的智能化发展催生了人工智能和机器学习等领域的研发与解决方案。机器人手臂在医疗、航空航天、军事等领域也发挥重要作用,推动相关技术的发展与创新。同时,机器人手臂的集成设计与模块化机构为自动化设备的制造与维护提供了便利。科技创新的推进将进一步提升机器人手臂的性能与功能,以满足不断变化的需求。

然而,机器人手臂在发展过程中仍面临一些挑战。首先是安全问题。机器人手臂与人类协同工作,安全风险不容忽视。需加强安全控制与监测系统的研发,确保人员安全。其次是成本问题。目前,机器人手臂的制造和维护成本相对较高,这限制了其在一些中小型企业的解决方案。需要不断降低机器人手臂的成本,提高其市场普及率。最后是社会接受度问题。机器人手臂技术对一些人来说仍然相对陌生和新颖,需要加强机器人手臂的宣传和教育,以提高公众对其的认知和接受度。

综上所述,作为自动化设备的重要组成部分,机器人手臂在提升生产效率、保障工作安全、促进技术创新方面发挥着重要作用。随着科学技术的不断进步与创新,相信机器人手臂将在各领域发挥更加重要的作用,为人们创造更加美好的生活和工作环境。