Introduction The LCD display is an integral component of CO2 laser equipment, serving as the interface through which operators monitor and control the laser processes. Selecting the right LCD display is critical to ensure efficient operation, precise control, and user satisfaction. This article explores key considerations for choosing LCD displays suitable for CO2 laser equipment and highlights various effective options available in the market.

High Resolution and Clarity

High resolution is paramount for clear visualization and precise control of CO2 laser processes. Displays with resolutions such as Full HD (1920×1080) or higher provide sharp imagery, enabling operators to monitor intricate details with precision. Additionally, displays with high pixel density offer enhanced clarity, ensuring accurate adjustments and monitoring during laser operations.

Durability and Resilience

The harsh operating conditions often encountered in industrial settings necessitate LCD displays that are robust and resilient. Displays with rugged construction, reinforced screens, and shock-absorbent features are better equipped to withstand vibrations, impacts, and other environmental stressors. Furthermore, displays with protective coatings or sealed components offer resistance to dust, moisture, and other contaminants, ensuring reliable performance in challenging environments.

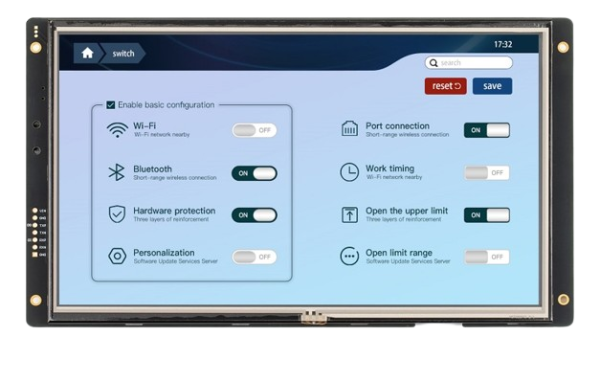

User-Friendly Interface

A user-friendly interface is essential for intuitive operation and efficient workflow. Displays with intuitive menus, clear labeling, and easily accessible controls simplify navigation and enhance usability. Touchscreen displays provide tactile feedback and streamline interaction, allowing operators to make adjustments and inputs directly on the screen, thereby improving efficiency and productivity.

Compatibility and Connectivity Compatibility with CO2 laser systems and peripherals is crucial for seamless integration and optimal performance. Displays with flexible connectivity options, such as HDMI, DisplayPort, and USB, facilitate easy connection to laser control systems and other devices. Additionally, displays that support common communication protocols ensure smooth data exchange and interoperability with laser equipment and software applications.

Energy Efficiency Energy-efficient displays help reduce power consumption and minimize operational costs while promoting sustainability. Displays with features such as LED backlighting, power-saving modes, and automatic brightness adjustment optimize energy efficiency without compromising performance. By conserving electricity and reducing carbon emissions, energy-efficient displays contribute to environmental conservation and cost savings for operators.

Conclusion Choosing the right LCD display for CO2 laser equipment is crucial for achieving optimal performance, reliability, and user satisfaction. By considering factors such as resolution, durability, user-friendliness, compatibility, and energy efficiency, operators can select a display that meets their specific requirements and enhances the functionality of their laser systems. Investing in a suitable LCD display ensures smooth operation, precise control, and efficient monitoring of CO2 laser processes, ultimately leading to improved productivity and profitability.