Form Fill and Seal (FFS) machines play a critical role in the packaging industry, automating the process of filling products into pre-formed bags or pouches. This article examines the suitability and advantages of TFT screens in enhancing the functionality and efficiency of FFS machines.

Introduction to Form Fill and Seal Machines

Form Fill and Seal machines are automated packaging systems used extensively across various industries to streamline the production of packaged goods. These machines integrate multiple operations including filling, sealing, and packaging into a single continuous process, improving productivity and consistency.

Evolution of Human-Machine Interfaces in FFS Machines

Human-Machine Interfaces (HMIs) in FFS machines have evolved significantly over time. Initially comprising basic controls and indicators, modern HMIs now incorporate advanced TFT (Thin-Film Transistor) screens that offer superior graphical capabilities, touch interactivity, and enhanced user experience.

The Technological Advantages of TFT Screens

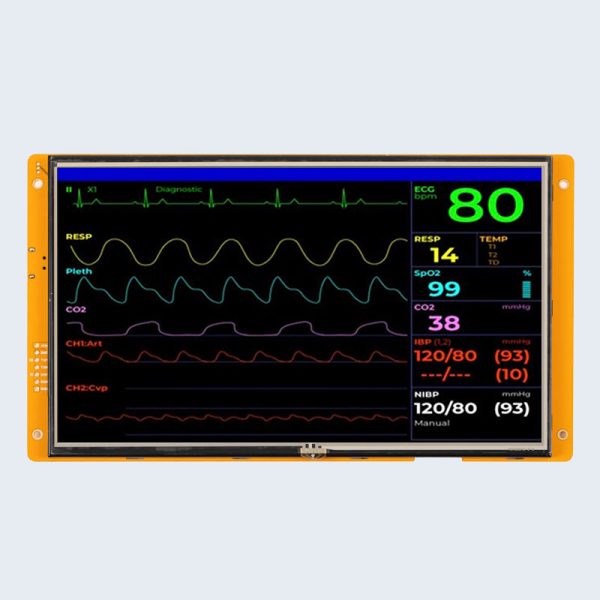

TFT screens provide several technological advantages that make them suitable for integration into FFS machines. These include high resolution for clear visualization of process parameters, robustness to withstand harsh industrial environments, and versatility in displaying complex graphical interfaces required for operator interaction.

Enhancing User Interaction and Control

Integration of TFT screen in FFS machines enhances user interaction by providing intuitive touch interfaces. Operators can easily monitor production parameters, adjust settings, and diagnose issues using graphical representations and interactive controls, thereby reducing training time and improving operational efficiency.

Customization and Flexibility in Interface Design

TFT screens allow for customizable interface designs tailored to specific FFS machine functionalities and user preferences. Operators can configure screens to display real-time production data, set parameters for different product types, and receive alerts or notifications for maintenance or operational issues.

Integration with Industry 4.0 and Smart Manufacturing

FFS machines equipped with TFT screens can integrate seamlessly with Industry 4.0 initiatives and smart manufacturing practices. Connectivity features such as Ethernet ports, wireless communication protocols, and compatibility with data analytics platforms enable real-time monitoring, remote access, and predictive maintenance capabilities.

Durability and Reliability in Industrial Environments

TFT screens are engineered to meet the stringent durability requirements of industrial environments. With features like scratch-resistant glass, dust and moisture protection, and wide operating temperature ranges, these screens ensure reliable performance even in challenging conditions typical of manufacturing facilities.

Improving Operational Efficiency and Quality Control

The use of TFT screens in FFS machines contributes to improving operational efficiency and quality control processes. Operators can precisely monitor filling accuracy, sealing integrity, and packaging consistency through detailed graphical representations and real-time data feedback, minimizing errors and waste.

Cost-Effectiveness and Return on Investment (ROI)

While TFT screens may represent a higher initial investment, their long-term benefits justify the cost. Enhanced productivity, reduced downtime due to intuitive troubleshooting capabilities, and improved product quality contribute to a favorable ROI over the lifespan of the FFS machine.

Future Trends and Innovations

Looking ahead, the future of TFT screen in FFS machines is promising. Advancements in display technology, including higher resolutions, energy efficiency, and integration with augmented reality (AR) for enhanced operator guidance, will further elevate the capabilities and functionality of these interfaces.

Conclusion

In conclusion, TFT screens have emerged as indispensable components in modern Form Fill and Seal machines, revolutionizing how operators interact with and control packaging processes. Their technological advantages, including high-resolution displays, touch interactivity, and durability, position TFT screens as optimal choices for enhancing efficiency, reliability, and flexibility in industrial packaging operations.

This article has provided a comprehensive overview of the suitability of TFT screens for FFS machines, emphasizing their role in driving technological advancements and improving operational outcomes in the packaging industry. As technology continues to evolve, TFT screens will continue to play a pivotal role in shaping the future of automated packaging solutions.