Food grain packing machines are critical in the food processing industry, automating the packaging of grains such as rice, wheat, and oats. This article investigates how TFT screens enhance the functionality, efficiency, and user experience in food grain packing machines.

Introduction to Food Grain Packing Machines

Food grain packing machines are designed to automate the process of weighing, filling, and packaging various types of food grains into bags or containers. These machines ensure accuracy, consistency, and hygiene standards in packaging, catering to the demands of food processing facilities worldwide.

Evolution of Human-Machine Interfaces in Food Grain Packing Machines

Human-Machine Interfaces (HMIs) in food grain packing machines have evolved significantly, driven by advancements in display technology. From basic digital displays to TFT screen, HMIs have transitioned to provide intuitive graphical interfaces that enhance operator control and monitoring capabilities.

Technological Advantages of TFT Screens

TFT screens offer several technological advantages that make them highly suitable for integration into food grain packing machines. These include high resolution for detailed visualization of packing parameters, touch sensitivity for easy operation, and robustness to withstand dust, moisture, and temperature variations in food processing environments.

Enhancing User Interaction and Control

The integration of TFT screens in food grain packing machines enhances user interaction and control. Operators can monitor filling accuracy, adjust packing parameters, and track production metrics through intuitive touch interfaces and graphical representations. This improves operational efficiency and reduces the likelihood of errors during packaging processes.

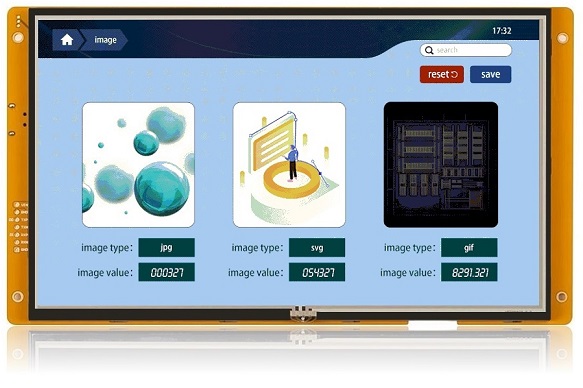

Customization and Adaptability in Interface Design

TFT screens allow for customizable interface designs tailored to specific food grain packing requirements. Operators can configure screens to display real-time production data, set packaging weights or quantities, and receive alerts for maintenance or operational issues, thereby optimizing machine performance and ensuring product quality.

Integration with Industry Standards and Regulations

Food grain packing machines equipped with TFT screens adhere to industry standards and regulations governing food safety and quality. Features such as easy-to-clean surfaces, stainless steel construction, and compliance with Hazard Analysis and Critical Control Points (HACCP) guidelines ensure hygienic operation and product integrity.

Connectivity and Data Management Capabilities

TFT screens facilitate connectivity options essential for data management in food grain packing machines. Integration with Ethernet, USB ports, and compatibility with data logging systems enable seamless data transfer, remote monitoring, and integration with enterprise-level software for production planning and quality control.

Durability and Reliability in Food Processing Environments

TFT screens are engineered to withstand the rigors of food processing environments. With features like shatter-resistant glass, IP-rated enclosures for protection against water and dust ingress, and resistance to cleaning chemicals, these screens ensure reliable operation and longevity in demanding conditions.

Improving Efficiency and Sustainability

The use of TFT screens in food grain packing machines contributes to improving efficiency and sustainability in food processing operations. Enhanced accuracy in weighing and filling processes reduces product wastage, while energy-efficient display technologies lower overall operational costs and environmental impact.

Cost Considerations and Return on Investment (ROI)

While TFT screens may involve initial investment costs, their long-term benefits in terms of operational efficiency, reduced downtime, and improved product consistency justify the investment. The ability to optimize packaging processes and meet stringent quality standards ensures a favorable return on investment over the lifespan of the equipment.

Future Trends and Innovations

Looking forward, future trends in TFT screens for food grain packing machines include advancements in display technology such as higher resolutions, increased touch sensitivity, and integration with artificial intelligence for predictive maintenance and process optimization. These innovations will further enhance the capabilities and performance of food grain packing machines.

Conclusion

In conclusion, TFT screens play a crucial role in enhancing the functionality, efficiency, and user experience of food grain packing machines. Their technological advantages, including high-resolution displays, intuitive touch interfaces, and durability, make TFT screens ideal for optimizing packaging processes in the food processing industry.

This article has provided an in-depth exploration of the suitability of TFT screens for food grain packing machines, highlighting their contributions to improving operational outcomes, meeting regulatory requirements, and driving sustainability in food packaging operations. As technology continues to advance, TFT screens will remain pivotal in shaping the future of automated food grain packing solutions.