适用于润滑机串口屏

在工业机械领域,润滑机在润滑各种机械部件、确保顺畅运行和防止磨损方面发挥着至关重要的作用。这些机器的核心功能在于串口屏,它为操作人员提供必要的信息和控制选项。选择适合润滑机的串口屏对于确保效率、可靠性和用户友好操作至关重要。本文将探讨适用于润滑机不同类型的串口屏及其各自的特点和优势。

理解串口屏在润滑机中的重要性

润滑机中的串口屏承担着多个关键功能:

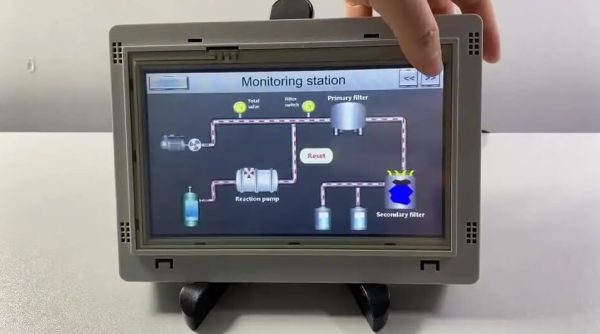

- 监控:显示油位、压力、温度和流量等实时数据,以监控机器性能。

- 控制:通过直观的用户界面,允许操作员调整设置、启动润滑循环并排查故障。

- 安全:显示异常条件或维护需求的警报和警告,确保安全运行并防止设备损坏。

- 集成:与润滑系统其他组件(如泵、阀门和传感器)接口,实现无缝协调和自动化。

适用于润滑机的串口屏类型

1. 工业级显示屏

特点:

- 坚固耐用的结构,可承受恶劣工业环境,包括灰尘、振动和温度波动。

- 高亮度,适用于明亮或户外环境。

- 延长使用寿命和可靠性,支持连续运行。

2. 触摸屏显示器

特点:

- 直观的触摸界面,便于导航和控制。

- 消除对外部输入设备的需求,简化操作。

- 适用于需要精确输入或交互的应用。

3. 面板安装显示器

特点:

- 设计用于集成到控制面板或机械外壳中。

- 紧凑型设计和可定制的安装选项,适用于空间受限的环境。

- 密封结构,防止灰尘、油污和湿气侵入。

4. 高分辨率显示屏

特点:

- 清晰锐利的图像质量,适用于显示详细数据和图形。

- 提升文本和图表的可读性,降低误读风险。

- 适用于需要精确显示关键参数的应用场景。

5. 远程显示屏

特点:

- 支持无线连接,实现远程监控和控制。

- 允许操作员从远程位置访问机器状态和设置,提升灵活性和便利性。

- 支持与集中控制系统集成,实现自动化和效率提升。

选择合适的串口屏的考虑因素

在为润滑机选择串口屏时,需考虑以下因素:

- 兼容性: 确保与现有硬件和软件系统兼容,包括通信协议和接口标准。

- 耐用性:选择结构坚固、采用工业级组件的显示屏,以承受润滑机器的运行环境。

- 用户界面:选择具有直观用户界面的显示屏,便于操作并减少错误或事故风险。

- 集成性:评估与润滑系统其他组件(如PLC、HMI和传感器)的兼容性,确保无缝集成和互操作性。

- 可扩展性:考虑未来扩展和升级选项,以适应不断变化的需求和技术。

适用于不同应用的额外串口屏

虽然润滑机依赖串口屏进行监控和控制,但其他应用也受益于合适的显示解决方案:

1. 农业机械

农业设备(如拖拉机、收割机和灌溉系统)中的串口屏为操作员提供土壤状况、作物健康和设备状态等关键信息。坚固耐用、阳光下可读性和触摸屏界面是户外应用的必要特性。

2. 海洋导航系统

海洋导航系统和船载仪表中的串口屏为船员提供GPS坐标、水深测量和天气预报等关键信息。防水结构、宽温度范围和防眩光涂层是海洋环境的必要特性。

3. 医疗成像设备

医疗成像设备(如超声波机器、MRI扫描仪和X光系统)中的串口屏使医疗专业人员能够可视化和分析诊断图像。高分辨率、色彩准确性和DICOM兼容性是医疗应用中的关键考虑因素。

4. 零售点销售系统

零售POS系统中的串口屏简化交易流程、展示产品信息并为客户提供互动体验。触摸屏界面、集成卡读卡器和时尚设计等功能可提升购物体验并简化结账流程。

5. 公共交通信息显示屏

公共交通系统(包括公交车、火车和机场)中的串口屏为乘客提供实时更新的班次、路线和服务中断信息。高亮度、宽视角和坚固耐用的结构是户外及高流量环境的必要条件。

结论

选择适合润滑设备的串口屏对于确保最佳性能、可靠性和用户满意度至关重要。通过考虑耐用性、可视性、触控功能、集成度及应用特定需求等因素,操作人员可选取符合润滑系统需求的显示屏。此外,串口屏在农业、海洋导航、医疗成像及零售等多个行业均有广泛应用,彰显其在现代科技驱动环境中的多功能性和重要性。